Common Furnace Problems Homeowners Face in Cypress: Causes, Troubleshooting, and Repair Solutions

Furnace problems in Cypress often stem from a mix of local climate stressors, aging components, and simple maintenance gaps that reduce heat output and increase energy use. For more information on maintenance, you can check our HVAC maintenance plan.

This guide explains the common furnace faults Cypress homeowners see—no heat, cold air output, strange noises, short cycling, and ignition or pilot failures—and gives safe, actionable troubleshooting steps and clear decision points for calling a professional. You will learn symptom-to-cause mappings, short homeowner checks you can perform safely, and red-flag indicators related to combustion and carbon monoxide risk. The article maps each major issue to quick DIY triage, a recommended next action, and how technicians diagnose underlying failures, with targeted examples for Cypress homes. Read on for step-by-step checks, EAV triage tables for rapid diagnosis, noise and short-cycling guides, and emergency response actions so you can protect comfort and safety this heating season.

Why Is My Furnace Not Heating in Cypress? Causes and Quick Fixes

A furnace that runs but does not produce heat results from control, combustion, or airflow failures where the burner or heat transfer process is interrupted. In Cypress, high indoor humidity and variable thermostat locations in older homes can amplify airflow and control problems, making a non-heating furnace more common during seasonal transitions. This section outlines the top mechanical and control causes, offers immediate homeowner checks, and provides a compact triage table to prioritize safety and efficient diagnosis. Follow the safe stop-conditions and seek professional help when combustion, gas supply, or suspected heat-exchanger problems are involved.

Different symptoms map quickly to probable causes and homeowner checks:

| Symptom | Probable Cause | Quick Homeowner Check |

|---|---|---|

| Furnace runs but no heat | Ignitor or pilot failure | Listen for ignition clicks; check thermostat calls for heat |

| No power to furnace | Tripped breaker or switch | Check furnace switch and circuit breaker |

| Weak or no airflow | Clogged air filter or closed vents | Inspect/replace filter; ensure vents open |

| Burner lights but cool air | Faulty gas valve or control board | Note flame color and consistency; do not tamper with gas valve |

This triage table helps prioritize safe checks and prepares useful observations to report to a technician. If checks do not restore heat or if you detect unusual combustion signs, stop further troubleshooting and schedule professional diagnostics.

What Are the Main Reasons a Furnace Stops Producing Heat?

Thermostat errors, ignition or pilot failures, and interrupted fuel or electrical supply are the most frequent reasons furnaces cease producing heat. A misprogrammed thermostat or dead batteries can prevent the furnace from receiving a call for heat, while electronic ignitors or pilot assemblies wear out and fail to light burners reliably. Electrical faults such as tripped breakers, blown fuses, or a switched-off furnace power disconnect also commonly interrupt operation. Additionally, safety limit switches and pressure or flame sensors may open to shut down burners when overheating or venting problems occur, which requires professional investigation before restart.

These control and combustion mechanisms link directly to simple homeowner checks such as verifying thermostat mode, power availability, and visible flame quality. Understanding these primary reasons supports safe, evidence-based decisions on whether to perform basic troubleshooting or to stop and call a qualified technician.

How Can Homeowners Troubleshoot Furnace No Heat Issues Safely?

Before attempting any inspection, confirm that safety controls like carbon monoxide alarms are functional and that you smell no gas or see visible flames or smoke. Perform a short, ordered checklist of safe diagnostic steps and stop immediately if you detect combustion abnormalities or a gas odor. The numbered steps below present a safe sequence for homeowners to follow and what to expect from each action.

- Check the thermostat: Confirm it is set to HEAT, the temperature setpoint is above room temperature, and batteries are fresh.

- Verify power: Inspect the furnace switch and circuit breaker; reset if tripped and wait a few minutes for control resets to complete.

- Inspect the air filter: Replace a visibly dirty filter and check return vents for obstructions to restore proper airflow.

After completing these steps, if the furnace still shows no heat or if you observe weak or yellow flames, stop further DIY work and contact a professional for combustion and gas-safety diagnostics. Accurate notes on what you observed will speed professional troubleshooting and repair.

What Causes Strange Furnace Noises in Cypress and How Can They Be Fixed?

Furnace noises range from harmless thermal expansion to serious mechanical distress indicating imminent failure; mapping noise types to likely sources allows homeowners to triage urgency. In Cypress homes, duct contraction from humidity changes and blower stress from clogged filters are common contributors to audible issues. This section categorizes noises, explains their likely sources, and presents safe first checks along with a short EAV-style table to guide next steps.

Common noises, their likely causes, and homeowner checks:

| Noise Type | Likely Source | Homeowner Check / When to Call |

|---|---|---|

| Banging or loud knocking | Ignition delay, expanding ducts, or oil burner issues | Check for one-time expansion; call pro if persistent or with flame problems |

| Grinding or screeching | Worn blower bearings or belt | Power off and inspect blower access panel; call pro if noise continues |

| Popping/clicking | Ductwork expansion or ignition misfires | Monitor for patterns; call pro if tied to loss of heat or combustion smell |

This table helps convert a sound into an investigative action and indicates when mechanical service is necessary. Persistent mechanical noises often signal wear that can reduce efficiency and should prompt timely repair.

Which Furnace Noises Indicate Serious Problems?

Loud or continuous banging, persistent grinding, or repetitive popping that coincides with performance loss are signs of serious mechanical or combustion issues. Banging that aligns with ignition events can indicate delayed ignition or combustion chamber problems and may stress the heat exchanger. Grinding or squealing typically comes from the blower motor bearings or misaligned belts that, if unaddressed, lead to motor failure and higher repair costs. Frequent popping that suggests combustion irregularities or blocked flue paths can imply elevated carbon-monoxide risk and requires immediate professional attention.

Because these noises often signal growing mechanical stress or combustion safety problems, do not ignore recurring or worsening sounds. Document when sounds occur, any associated performance changes, and report these observations when arranging professional service for faster, targeted diagnostics.

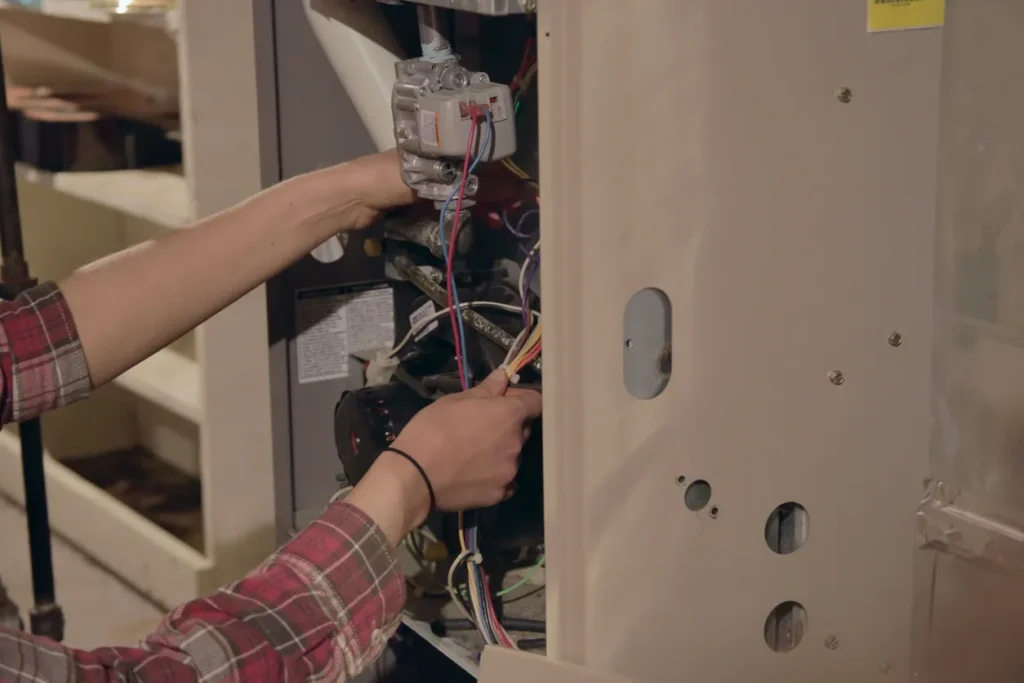

How to Identify and Repair Common Noise Sources Like Blower Motors and Heat Exchangers

Start noise diagnosis with safe visual checks performed with power off: inspect the blower compartment for loose screws, debris, or belt damage and check the duct seams for loose sections that beat during startup. Lubrication needs and belt replacement are common repairs that a technician can complete quickly, but access to internal motor mounts and bearings typically requires professional service. Heat exchanger concerns cannot be repaired safely by homeowners due to combustion and CO risk; any suspected heat-exchanger crack or flame-rollout should prompt immediate shutdown and service.

Temporary fixes like securing loose duct straps or replacing a worn belt may restore quiet operation, but persistent or combustion-linked noises require certified inspection to prevent safety hazards and protect system life.

Why Is My Furnace Blowing Cold Air in Cypress? Troubleshooting and Solutions

A furnace that runs but blows cold air often reflects control mode settings, ignition or fuel delivery faults, or airflow problems that prevent the heated air from reaching the living space. In Cypress, issues like thermostat fan-only mode or heat pump systems operating in auxiliary modes can create the illusion of furnace cold-air problems; confirming system type and thermostat mode is the first essential step. This section lists likely causes, directs homeowners through precise checks, and outlines when combustion or gas-related signs require professional intervention.

Below are typical causes and immediate indicators to guide homeowner triage:

- Thermostat mode or fan-only setting: Confirm thermostat is set to HEAT and fan to AUTO rather than ON.

- Ignitor or pilot failure: Furnace may run the blower without burner ignition; listen for ignition attempts or multiple lockouts.

- Gas supply or valve issues: Intermittent or no gas flow can allow blower operation without heat; check for other gas appliances affected.

If basic thermostat and filter checks do not resolve cold airflow, or if you detect irregular flame color, persistent lockouts, or a gas odor, evacuate if necessary and seek immediate professional service. Carbon monoxide safety devices should be functional and checked as part of any combustion-related diagnosis.

What Are the Common Causes of Cold Air from a Furnace?

Cold air output is commonly caused by incorrect thermostat settings, a failed ignitor or pilot, stuck gas valves, or restricted airflow from clogged filters or blocked returns. Thermostat misconfiguration can be corrected immediately, but ignition or gas-valve faults often require diagnostic equipment and safe gas handling by a technician. Airflow restrictions can make warm air insufficiently distributed, producing cold pockets even when the burner fires normally. Diagnosing whether the issue is combustion-related or airflow-related helps prioritize safe remedies and service needs.

Careful observation of flame color, burner cycling behavior, and airflow at registers provides valuable clues to professionals and helps you determine whether immediate emergency actions are warranted.

When Should You Call a Professional for Furnace Cold Air Problems?

Call immediately if you smell gas, see abnormal flames (yellow or flickering), or if the furnace repeatedly locks out after failed ignition attempts. Schedule same-week service for persistent cold-air output after replacing filters and confirming thermostat and breaker status. If carbon monoxide alarms activate or occupants develop CO symptoms—headache, nausea, dizziness—evacuate and seek medical attention while arranging emergency furnace inspection. For non-urgent yet unresolved cold-air issues, document thermostat behavior and burner observations to share with the technician to expedite diagnosis.

How Does Furnace Short Cycling Affect Cypress Homes and What Can Be Done?

Short cycling—when the furnace turns on and off rapidly—reduces comfort, wastes energy, and accelerates wear on components like the ignition system and blower motor. In Cypress homes, short cycling frequently follows clogged filters, thermostat placement near heat sources, or control and safety-limit trips caused by restricted airflow. This section defines short cycling, explains how to detect it, and provides an EAV-style comparison table showing common causes, triggers, and recommended fixes to guide homeowner action and professional diagnostics.

Short cycling shortens equipment life and increases utility bills by preventing full heating cycles and causing repeated start-stop stress on components. The table below helps match observed cycling patterns to likely causes and practical fixes.

| Short Cycling Cause | Trigger | Fix / Professional Action |

|---|---|---|

| Restricted airflow | Dirty filter, closed vents | Replace filter; open/clear vents; call for duct testing |

| Thermostat placement | Near heat source or sunlight | Relocate thermostat or use a smart placement solution |

| Oversized furnace | Rapid room warm-up then cut out | Consult for system resizing or zoning improvements |

What Causes Furnace Short Cycling and How to Detect It?

Short cycling arises from airflow restrictions, thermostat configuration or placement, control-safety trips, or oversized equipment relative to the home’s heat load. Detect it by timing on/off cycles: cycles under five minutes often indicate short cycling rather than normal operation, while normal cycles typically run 10–15 minutes depending on system and load. Logging cycle durations over a 30–60 minute period and noting recent maintenance or filter changes gives technicians useful diagnostic context. Record whether cycles correspond to thermostat calls for heat or whether the furnace attempts to start multiple times before shutting down.

This detection approach yields objective data to communicate to a technician and helps prioritize fixes such as filter replacement, thermostat relocation, or a full system evaluation.

What Are the Best Steps to Fix Furnace Short Cycling?

Start with immediate homeowner steps: replace or clean the air filter, verify that vents and returns are open and unobstructed, and check thermostat batteries and placement away from heat sources. If short cycling persists after these fixes, schedule professional airflow testing, safety-limit inspection, and control-system diagnostics to identify the root cause. Long-term solutions may include improving duct balance, adding zoning, or resizing equipment for the home’s load to prevent recurring short cycles. Timely professional intervention avoids repeated component stress and restores efficient, reliable heating.

These layered steps—from simple maintenance to professional diagnostics—create a cost-effective path to resolving short cycling with minimal downtime.

How Do Pilot Light and Ignition Problems Impact Furnace Performance in Cypress?

Pilot and ignition systems are fundamental to combustion heating; failures lead to intermittent heat, lockouts, and safety hazards including gas buildup or incomplete combustion. In Cypress, seasonal changes and dust-laden ducts can increase ignition failures and pilot outages, and homeowners should recognize signs early and apply safe relighting protocols only when applicable. This section distinguishes pilot versus electronic ignition systems, lists observable failure signs tied to combustion safety, and provides a safe relighting checklist for older pilot-equipped furnaces with explicit stop conditions.

Understanding the difference between a standing pilot and an electronic ignition helps determine whether a homeowner can safely attempt a relight or must call a technician to avoid gas or CO risks. The guidance below focuses on safety-first procedures and clear criteria to stop.

What Are the Signs of Pilot Light Failure or Flickering?

Signs include a weak, yellow, or flickering flame; frequent outages after relighting; sooting around the burner area; or repeated furnace lockouts. A steady blue flame indicates proper combustion, while yellow or lazy flames suggest incomplete combustion or burner contamination, which elevates carbon monoxide risk. Repeated pilot outages often point to a failing thermocouple, weak gas pressure, or venting issues that require professional testing. If you smell gas or if a carbon monoxide alarm activates, evacuate immediately and seek emergency assistance rather than attempting further troubleshooting.

Early recognition of these signs and immediate safety actions reduce the risk of exposure and help technicians target the right ignition or venting repairs.

How Can Homeowners Safely Relight or Troubleshoot Pilot Light Issues?

If your furnace uses a standing pilot and you detect no gas smell, follow the manufacturer’s pilot relighting procedure: turn the control knob to OFF and wait several minutes, then to PILOT while depressing the knob and using the igniter or match per instructions; release when a steady blue pilot is established. Always ensure adequate ventilation and verify CO alarm operation before restarting the furnace fully. Stop immediately and call a professional if the pilot will not stay lit, if you smell gas, or if relighting results in abnormal flame color. Electronic ignition systems do not support homeowner relighting; repeated lockouts or electronic faults require diagnosis by a qualified technician.

These steps prioritize occupant safety while allowing limited, controlled homeowner intervention on appropriate systems.

When Should Cypress Homeowners Call for Emergency Furnace Repair?

Certain symptoms require immediate emergency service because they pose safety hazards to occupants or risk major equipment damage. Red-flag signs include the smell of natural gas, carbon monoxide alarm activation, flame roll-out, visible fire or smoke, and total loss of heat during freezing conditions.

If you encounter a smell of gas, see active flame roll-out, or your CO alarm sounds, evacuate the home immediately, call emergency services or your gas utility from a safe location, and do not re-enter until given the all-clear. For non-life-threatening but urgent issues—such as repeated ignition lockouts during a cold snap—shut off the furnace power and schedule emergency service to avoid equipment failure and prolonged exposure to cold.

In all combustion-related scenarios, prioritize verified CO-detector functionality and document symptoms for the responding technician.

What Are the Warning Signs That Require Immediate Professional Help?

Warning signs that demand emergency help include the odor of natural gas in the home, activation of carbon monoxide alarms or symptoms like severe headaches and dizziness, visible flame roll-out or smoke from the furnace, and an inability to maintain heat during freezing conditions that threaten pipes or health. If you detect any of these signs, evacuate everyone from the home, move to a safe distance, and contact emergency services and your gas company as applicable. Do not attempt to operate or restart the furnace if the gas is suspected to be present or if combustion irregularities are visible. Prompt professional response mitigates risk to life and property and prevents escalation of damage.

Clear, immediate evacuation and contacting emergency responders are the correct first steps for every red-flag scenario.

How Does Climate Experts Heating Provide Fast and Reliable Furnace Repair in Cypress?

Climate Experts Heating, Ventilation, and Air Conditioning responds to local furnace emergencies with focused diagnostics and service scheduling designed for quick resolution and clear communication. Their approach emphasizes rapid triage of combustion and safety-related faults, prioritized scheduling for emergency calls, and transparent guidance on next steps so homeowners understand whether a repair, temporary safe-shutdown, or replacement is appropriate. For Cypress residents seeking timely service and straightforward estimates, Climate Experts Heating positions itself as a local option able to coordinate appointments and safety-focused repairs efficiently.